Why did we make the design change we did for each boat?

- Aug 14, 2025

- 7 min read

Authors Ian Gaines and Eric Roehl

The First Boat AKA Unit 1

1975 SF20 Sea Craft 20’ – Major Design Modifications

The 1975 Safari Sea Craft underwent four significant structural and functional upgrades to enhance its performance, usability, and durability. Each modification was carefully engineered to preserve the vessel’s integrity while modernizing critical systems.

1. Helm Redesign and Electrical Access Improvements

The helm was substantially reconfigured to improve storage capacity and accessibility. A forward-facing seat was integrated into the helm station, creating additional storage space that now houses two marine batteries and the primary power cutoff switch.

Additionally, an access hatch was installed on the forward-facing side of the helm, allowing for a swing-out electrical board. This design eliminates the need for personnel to crawl under or into the helm compartment during electrical maintenance, improving both safety and serviceability.

2. Transom Reconstruction

The original transom and engine well were removed and replaced with a new full height transom using a custom-fabricated mold. The new transom is approximately 3 inches thick and constructed from three layers of ¾-inch marine-grade plywood, each laminated with fiberglass and interleaved with fiberglass matting.

+This method ensured structural rigidity while preserving the original transom angle and pitch. The enhanced design accommodates the addition of an aftermarket swim platform with a built-on engine bracket, enabling the engine to be mounted at the rear edge of the platform for better weight distribution and deck space utilization.

3. Composite Rear Bench Seat Integration

A new rear bench seat was engineered and installed using composite fabrication techniques. The bench was precisely sized to fit the footprint of the original transom area. Initially prototyped in wood to ensure proper fit and ergonomics, it was later molded and fabricated using advanced composite materials.

The bench includes an integrated cooler and live well system, providing multifunctional utility for recreational or fishing use. The completed unit was securely bonded to the deck using modern marine-grade adhesives and structural bonding compounds to ensure a permanent, watertight installation.

4. Deck Replacement and Core Material Upgrade

Due to moisture intrusion over the years, the original plywood-core deck had deteriorated. The old deck was removed and used as a template for fabricating a new, high-performance deck. A flat casting table was used to laminate the new section, ensuring a smooth, level surface.

The replacement deck was constructed using Vinyl Ester resin, PVC foam core, and Pieces of high-density plastic lumber (Aquaplas 5) for all through-hull penetrations. Chopped strand and stitched fiberglass reinforcements were layered into the laminate to ensure structural integrity and resistance to future water intrusion. A T-top was added for additional shade and protection from the weather

Electronics

The electrical system and electronics were upgraded with new modern systems and wiring.

The Second Boat AKA Unit 2

1976 Master Angler Sea Craft 20’

Comprehensive Structural and System Upgrades on Vessel

A series of extensive structural and functional upgrades were performed on this vessel to improve durability, safety, and functionality. The process began with the complete disassembly of the boat, which included the removal of both the deck and liner from the hull to allow unobstructed access to internal components.

Deck and Liner Core Replacement

Deck:

The deck was inverted to facilitate the removal of the deteriorated plywood core. Once the core was extracted, we installed high-density synthetic plastic inserts at all locations subject to through-hull penetrations to ensure long-term durability and resistance to water ingress. The remainder of the deck area received closed-cell PVC foam core, selected for its superior mechanical properties and resistance to moisture. Pieces of high-density plastic lumber (Aquaplas 5) was added for hard points and screw retention The entire surface was then encapsulated using vinyl ester resin in conjunction with chopped strand mat and stitched fiberglass reinforcements to maximize structural integrity and laminate bonding.

Liner:

The liner underwent a similar process. After inverting it, all plywood core material was removed. Synthetic plastic inserts were placed in high-load and fastener-retention areas, particularly where through-hull components and mechanical fastenings would be located. The rest of the liner was rebuilt using PVC foam core and encapsulated using the same fiberglass and resin layup schedule as the deck. Once cured, the liner was flipped back over, and aft storage compartments were fabricated and integrated. These compartments now house the freshwater and seawater pump systems, enhancing system organization and accessibility.

In addition, four integrated deck support structures were engineered into the liner assembly. These supports replaced the previously used method of fastening wooden blocks with screws, providing a far more robust and permanent solution for deck-load distribution.

Custom Fabricated Storage Units and Live Well

The port and starboard storage units, along with a centralized live well, were custom fabricated using flat fiberglass sheet stock. All component parts were designed using CAD software and nested for precise CNC router cutting. The panels were then assembled into box structures, bonded with fiberglass, and structurally reinforced. After assembly, all units underwent fairing and finish work, followed by final paint application to match the deck aesthetics and ensure marine-grade durability.

Helm Access Redesign

The helm was reconfigured for improved maintenance access. A forward-facing access hatch was installed, allowing for a swing-out electrical panel. This redesign significantly enhances serviceability by eliminating the need for personnel to crawl under or inside the helm compartment during electrical work. The result is improved technician safety and faster maintenance turnaround. A T-top was added for additional shade and protection from the weather

Transom Reinforcement and Modernization

The transom was significantly upgraded by eliminating the original notched engine mount area. A solid Coosa composite core was installed, built up to a total thickness of 2 inches for optimal strength. This new transom structure was encapsulated using vinyl ester resin and a combination of chopped strand and stitched fiberglass reinforcement layers. The materials and layup schedule were selected specifically to ensure long-term resistance to water intrusion and structural fatigue. Importantly, the transom angle and pitch were preserved, maintaining original performance characteristics while accommodating the addition of an aftermarket swim platform with a built-on engine bracket. The engine can now be mounted flush to the swim platform aft edge, optimizing weight distribution and freeing up valuable deck space.

Electronics and motor

A new 150 HP Yamaha outboard motor was installed with all new wiring and gauges. The electrical system and electronics were upgraded with new modern systems and wiring. This includes Garmin MFD with chart platter and fish finder, Fusion entertainment system, VHF radio, and Shadowcaster RGBW LED lightings throughout the boat. To make anchoring easy and user friendly, a Maxwell vertical anchor winless is mounted on the bow with a rope / chain storage locker directly below it.

The Third boat AKA Unit 3

1976 Master Angler Sea Craft 23’

Deck and Liner Core Replacement

Deck Reconstruction

To enable the removal of the deteriorated plywood core, the deck was inverted. Upon extraction of the compromised material, Pieces of high-density plastic lumber (Aquaplas 5) inserts were installed at all locations subject to through-hull penetrations. These inserts were chosen for their exceptional resistance to water intrusion and long-term dimensional stability under load. The remaining deck area was re-cored using closed-cell PVC foam, a material selected for its outstanding compressive strength, moisture resistance, and compatibility with advanced composite laminates.

Following core installation, the entire deck surface was encapsulated using vinyl ester resin, combined with layers of chopped strand mat (CSM) and stitched fiberglass fabrics. This multi-axial layup schedule was engineered to optimize mechanical performance, improve resin-to-glass bonding, and deliver a robust laminate capable of withstanding torsional and impact loads over extended service life.

Liner Reconstruction

The liner underwent a parallel structural enhancement. After inverting the component, all existing plywood core was removed. Pieces of high-density plastic lumber (Aquaplas 5) inserts were strategically placed in high-load areas and regions requiring enhanced fastener retention, particularly in zones accommodating through-hull fittings and mechanical hardware.

The remaining liner area was rebuilt with closed-cell PVC foam core and reinforced using the same resin and fiberglass layup protocol applied to the deck, ensuring consistent mechanical and chemical properties throughout. Once the laminate was cured and the structure stabilized, the liner was reoriented to its functional position. Aft storage compartments were then fabricated and integrated into the liner, serving as housing for the freshwater and seawater pump assemblies. This redesign improved overall system layout, enhanced accessibility, and facilitated maintenance operations.

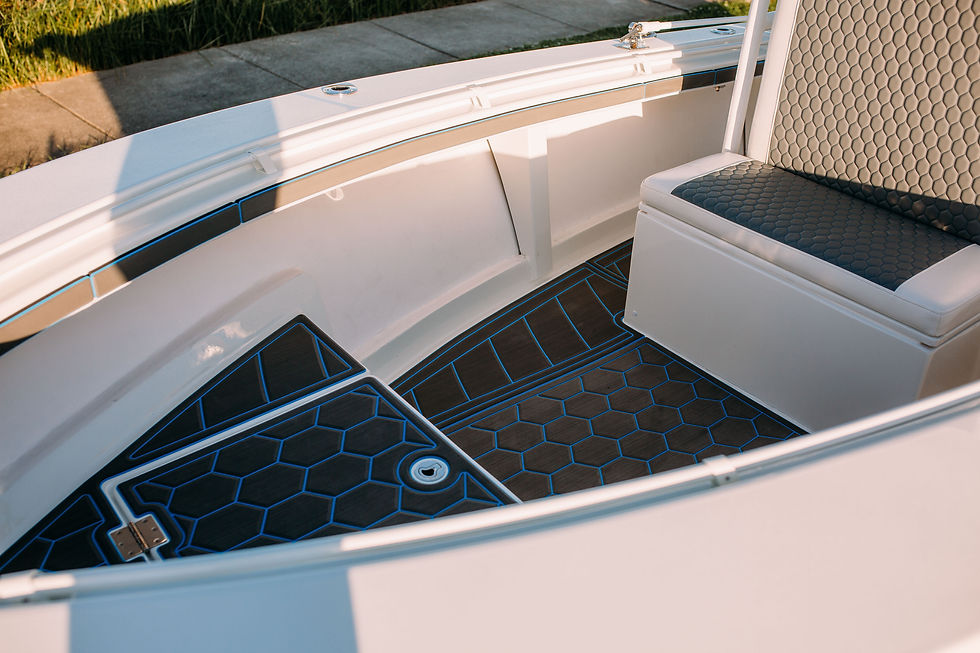

Aft Seating and System Access

A custom aft bench seat was constructed and mounted between the integrated storage compartments on the transom. An access hatch was incorporated beneath the seating area, providing direct access to critical hull-mounted systems, enabling efficient serviceability and future component replacement.

Helm Modifications and Cage Integration

To accommodate spatial constraints within the cage assembly area, the helm structure was custom modified. It was sectioned and reassembled with a 6-inch reduction in width to ensure proper fitment. Additionally, a structural cage was fabricated to support a newly integrated composite hardtop. This hardtop includes embedded lighting and audio components, offering both functional and aesthetic enhancements.

A molded fiberglass leaning post was also introduced, featuring an integrated live well system. To minimize its deck footprint and preserve available working area, the live well design was optimized for compactness without compromising capacity or accessibility.

Transom Reinforcement and Redesign

Significant structural improvements were made to the transom by removing the original notched engine mounting area. A solid Coosa composite core was installed and built up to a total thickness of 2 inches to maximize load-bearing capacity and mitigate long-term fatigue. This composite transom was encapsulated using vinyl ester resin and reinforced with alternating layers of CSM and stitched fiberglass for superior strength and water resistance.

The original transom angle and pitch were retained to preserve the vessel’s hydrodynamic performance and ensure compatibility with existing propulsion geometry. Additionally, the transom was engineered to support the flush mounting of an engine along the trailing edge of a newly incorporated swim platform with built on engine bracket. This adjustment not only improved weight distribution but also enhanced aft deck usability and accessibility.

Electronics and motor

A new 300 HP Yamaha outboard motor was installed with all new wiring and gauges. The electrical system and electronics were upgraded with new modern systems and wiring. This includes Garmin MFD with chart platter and fish finder, Fusion entertainment system, VHF radio, and Shadowcaster RGBW LED lightings throughout the boat. A Garmin radar was also added to complete the electronics package. To make anchoring easy and user friendly, a Maxwell vertical anchor winless is mounted on the bow with a rope / chain storage locker directly below it.

All three vessels were initially coated with a high-build primer to establish a uniform surface and to ensure proper adhesion of the subsequent paint layers. Following the curing period, each surface underwent a thorough sanding and surface preparation process to achieve optimal smoothness and cleanliness.

The chosen topcoat was Imron® Industrial Single-Stage Polyurethane Enamel, selected for its exceptional durability, long-term weather resistance, and high-gloss finish—all critical attributes for marine environments. This paint system also streamlines application by eliminating the need for a separate clear coat, delivering a robust finish in a single stage.

The color scheme was strategically selected based on current market trends and factory outputs, ensuring that the final aesthetic remained both contemporary and competitive within the marine industry.

Comments